flash sterilization

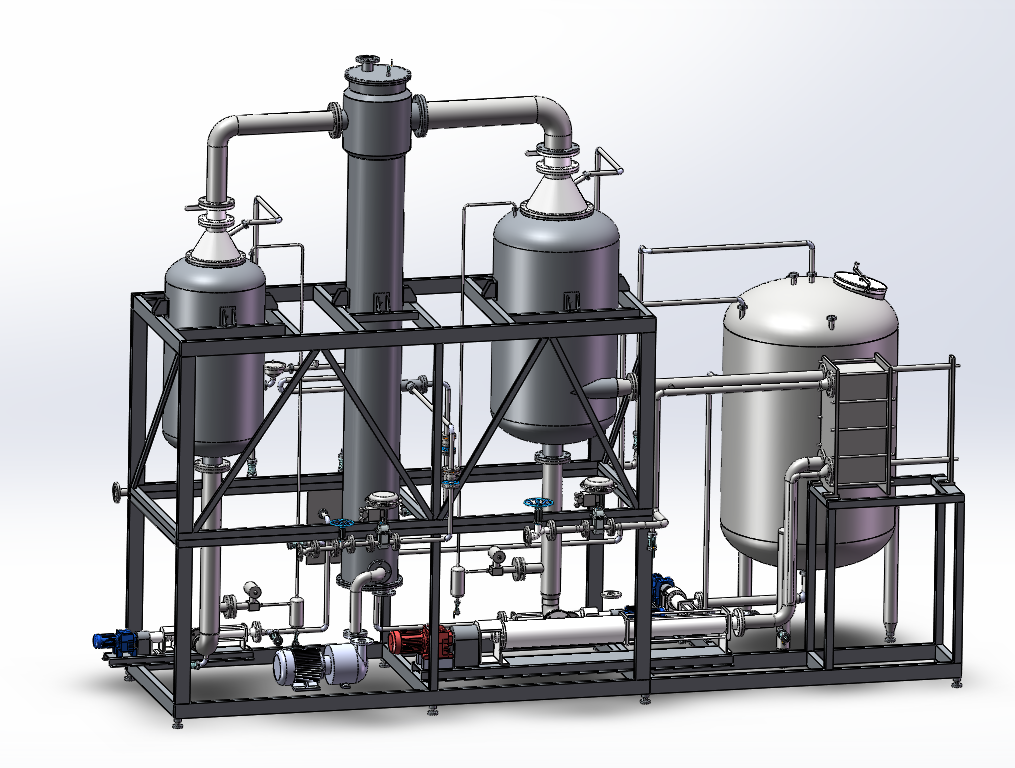

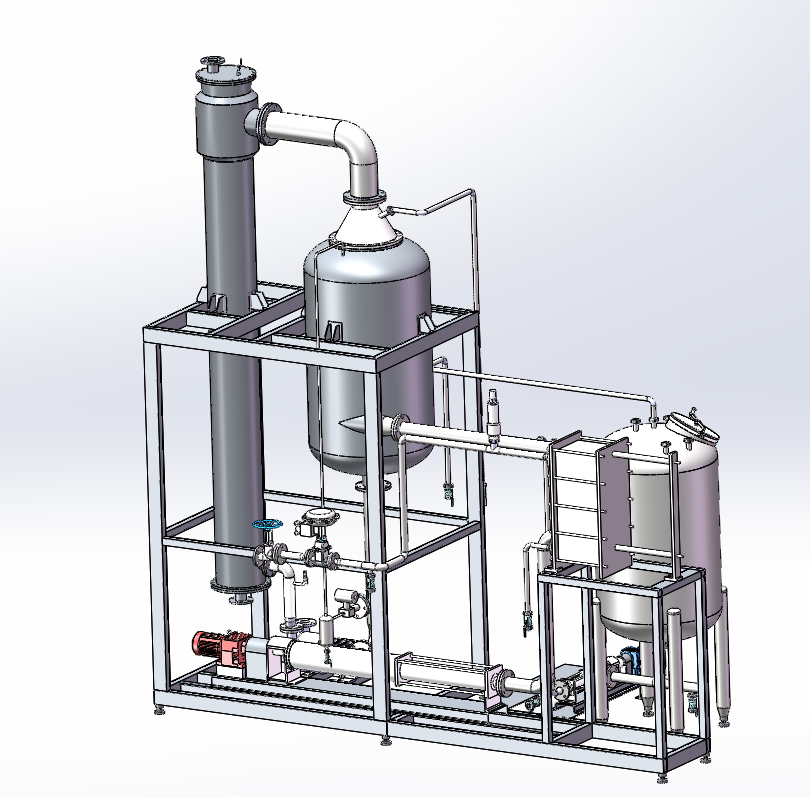

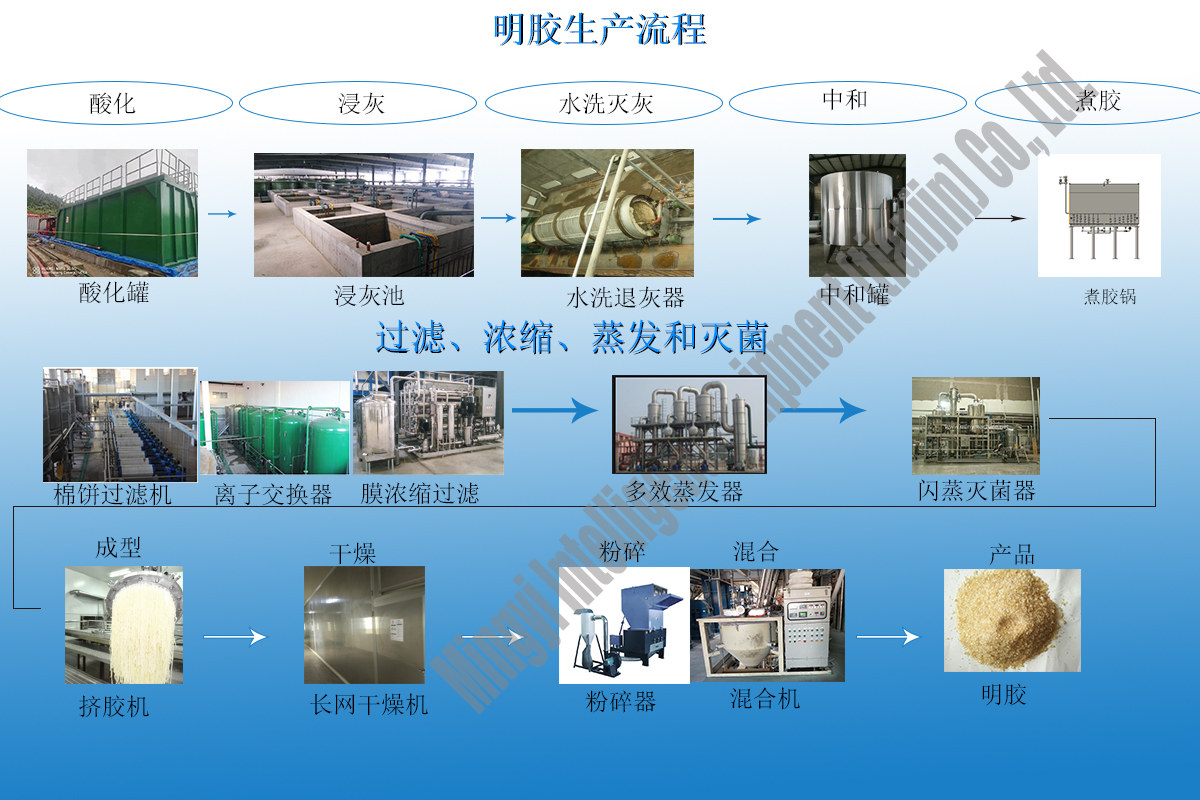

High temperature instantaneous sterilization is an important link in the production of gelatin. The concentrated gelatin liquid is transported by the feed balance tank screw pump to the plate heat exchanger for preheating.75℃-80℃, the concentrated glue solution is mixed with steam through a steam ejector and heated to sterilization temperature (140℃) thick glue passes through the holding tube for about4-6seconds. Through the interception valve into a certain degree of vacuum under the flash tank, at this time the pressure of the gelatin solution suddenly decreased, the water contained in the partial vaporization, the temperature instantaneously dropped50-53℃, the sterilized gelatin solution is continuously extracted by the screw pump at the lower part of the flash evaporator, which is an indispensable equipment in the gelatin production process. The higher the concentration of gelatin liquid before entering the extruder, the lower the operating energy cost, so it is necessary to set up flash evaporation equipment and flash evaporation sterilizer before entering the extruder.The company according to different customers, different output, custom processing flash sterilizer andand flash equipment.

Product Center